WVU Today

As alternative energy sources have become necessary to decrease global carbon emissions and meet growing energy demands, researchers at West Virginia University had ideas that came bubbling to the top — literally.

As part of the American-Made Geothermal Manufacturing Prize competition, a challenge designed to spur innovation and address manufacturing challenges in geothermal environments, associate professor Terence Musho and Berry Chair Emeritus Nigel Clark in the Statler College of Engineering and Mineral Resources, have developed a new airlift approach to optimize current geothermal pump technologies.

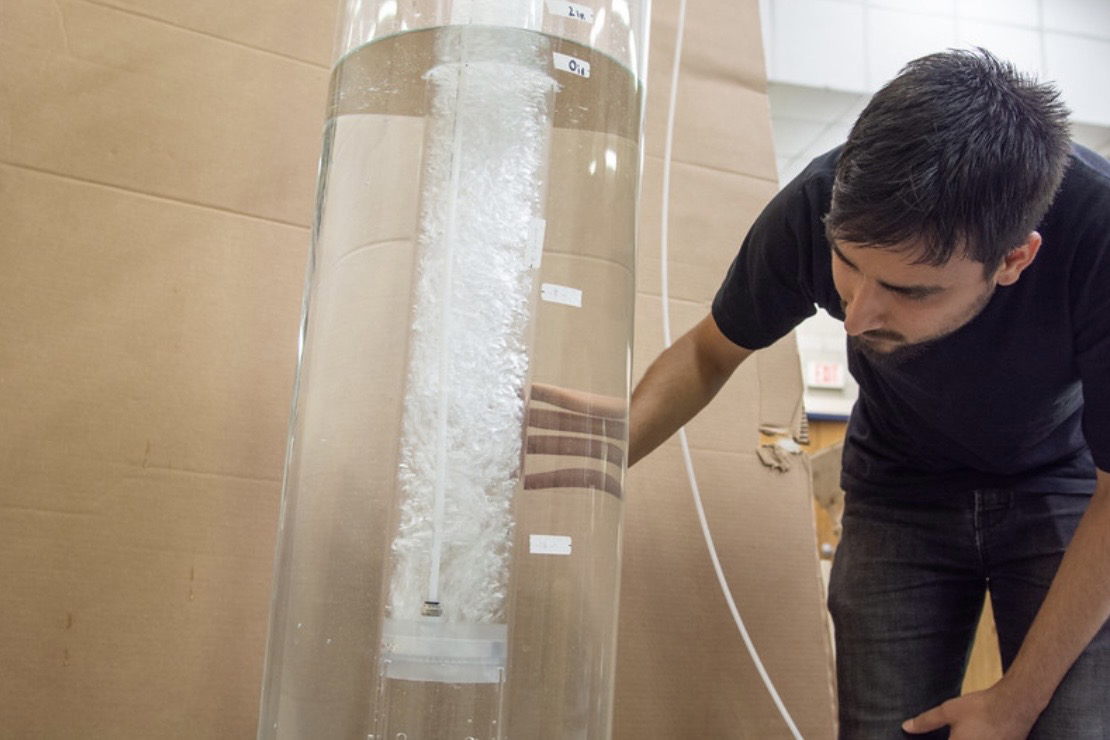

The two most common methods of bringing geothermal fluids to the surface are by using a line shaft pump or a submersible pump, although both methods have limitations. The method proposed by the engineers employs a 3D-printed device — a sparger head — to generate bubbles and lift water to the surface.

“Improved design of the sparger head for airlifts will revolutionize what the industry has been doing and eliminate the line shaft pump,” Musho said. “We can access much deeper geothermal wells, which typically have higher temperatures, which is better for direct usage and energy generation type applications.”

By injecting air deep into a geothermal well, it then rises to interact with geothermal fluids. As the air bubbles rise to the top of the well, an exchange in momentum causes the geothermal fluids to rise.

According to Musho, the technology works in a similar way to an automatic drip coffee maker. Typically, the water boils and travels up a tube to the top; instead of boiling the water, this method injects air into the water relying on the same buoyancy force to bring fluids up to the surface.

“The focus of this project relies on the efficient creation of bubbles,” Musho said.

“The software-based optimization will provide a more efficient operating environment by tailoring bubble generation for a given well condition.”

The advantages of geothermal energy production are many: unlike wind and solar, geothermal power plants produce electricity around the clock, modern plants emit no greenhouse gases and have a smaller physical footprint than other energy-generating plants, according to the DOE.

Musho and Clark teamed up with industry collaborators Dan Hand, a professional engineer from Sustainable Engineering LLC, and Roy Mink from Mink GeoHydro Inc, for the competition. The researchers are working within the Oak Ridge National Laboratory’s Manufacturing Demonstration Facility to use their state-of-the-art 3D metal printers.

As semifinalists of the competition, the team will make their submission for the Make Phase of the competition in November, if their technology is selected, it will be tested on working geothermal wells and the Statler College team will be eligible for up to $250,000 in cash prizes and up to $50,000 in vouchers.

TWEET @DominionPostWV